- [新聞]-->烏斯特質量測試在中國

- [新聞]-->烏斯特高科技儀器制造商

- [新聞]-->超越分級 了解和預防紗疵

- [產品]-->纖維工藝控制系統

- [產品]-->新型纖維測試儀器

- [產品]-->化纖長絲紗線質量控制

產品推薦

產品分類

聯系方式

- 聯系人:

- 郵 箱:sales@uster.com

- 地 址:上海市遵義路100號虹橋上海城A棟1801室

- 電 話:021-62856656

- 傳 真:021-62856253

- 網 址:http://www.uster.com

清紗新時代

發布時間:2013-11-14

清紗新時代

A new era in yarn clearing

客戶的反饋彰顯了新一代USTER®QUANTUM 3帶給客戶的影響及效益

Customer feedback underlines theimpact and benefits of the new-generation

USTER® QUANTUM 3

2013年10月16日瑞士烏斯特——USTER®QUANTUM 3 清紗器發布于2012年9月,在操作簡單、應用范圍以及為客戶帶來的效益方面取得了巨大的飛躍。新一代的系統將清紗帶入了一個全新的時代,系統會自動推薦一個最佳的切紗設定,并且紗體概念的應用提供了快速的質量參考。烏斯特在全球范圍內發布了這一款清紗器,并隨即基于紡廠的實際應用狀況仔細回顧了這些客戶的經驗。

Uster, Switzerland, October 16, 2013 –The launch in September 2010 of the USTER®QUANTUM 3 yarn clearer was a massiveleap forward in range of capability, ease of use and customer benefits. Thisnew-generation system propelled yarn clearing into a new era, with itscapability to suggest optimum cut settings automatically and its use of theYARN BODY concept to provide an instant quality reference. USTER launched theclearers globally and subsequently undertook a detailed review of customerexperiences, based on practical use under mill conditions.

創新是USTER®QUANTUM 3 研發的核心。首次以來,一款全新的清紗器超越了人們的普遍期望——推薦清紗設限以及預測切次水平。異物清除性能得到了極大的提升,能識別有色異物并進行選擇性地清除那些可能影響織物質量的紗疵。丙綸檢測時也涵蓋支數變異以及周期性紗疵檢測功能。簡單、安全的清紗是目標,根本目標還是幫助紡廠提升質量及產能。

Innovations were at the core of the USTER? QUANTUM 3 development. For the first time, a yarn clearer went beyond normal expectations - with its ability to propose clearing limits and predict cut levels. Foreign matter clearing was dramatically upgraded, with the ability to see colored defects and remove selectively the faults likely to affect fabric quality. Polypropylene detection capability was also extended to cover count variation and periodic faults. Simple, errorfree clearing was the aim, with the ultimate goal of helping spinners raise quality and productivity.

來自全球的最初反響非常好:客戶對產品留下了深刻印象。盡管產品問世前的測試確立了對該產品的信心,但是烏斯特還是決定用實際證據來支持這一點,通過大范圍的工廠訪問,從客戶那里拿到了第一手關于使用環境、生產應用和質量需求的反饋。新型清紗器幫助客戶實現了所需價值嗎?反饋表明確實實現了,并且一種全新的清紗方法也隨之誕生了。

Initial reactions around the world were positive: customers were said to be quite impressed. Prelaunch testing had confirmed initial confidence in the product, but USTER determined to support this with practical evidence, visiting spinning mills to get firsthand feedback from customers across a wide range of mill environments, applications and quality requirements. Was the new clearer delivering the benefits customers needed? Feedback suggested it was, and that a new approach to yarn clearing was born.

鐵的事實會滋生驚喜

Hardfacts can spring surprises

如今——首次安裝后33個月,近50萬個USTER®QUANTUM 3 銷售出去了——這一數字連烏斯特專家都感到驚喜。這些清紗器安裝在全球10000多臺自動絡筒機上,如中國、印度、土耳其、巴基斯坦、孟加拉、印度尼西亞、越南、韓國、意大利、埃及等紡織熱點地區,還有諸如西班牙、阿根廷、危地馬拉、坦桑尼亞、俄羅斯以及烏茲別克斯坦等小規模紡織國家。使用工廠包括從自絡機的初次使用者到有著很高質量要求的經驗豐富的使用者。使用環境溫度橫跨10到53攝氏度,相對濕度從20%到80%。超過300種纖維產品,包括傳統的棉、滌綸、粘膠及其混紡,還有諸如亞麻、莫代爾、天絲、蠶絲、羊絨、彈力氨綸絲以及非彈力絲包芯紗等類型。這些應用事實證明了USTER®QUANTUM 3 足以勝任各種不同的生產環境、應用以及期望。但是客戶從哪些方面來提升質量和產能呢?

Today 33month after the first installations, and with half a million USTER®QUANTUM 3 clearers sold the facts havesurprised even USTER's own experts. The clearers are now installed in over10.000 automatic winders around the world, in textile hotspots like China,India, Turkey, Pakistan, Bangladesh, Indonesia, Vietnam, Korea, Italy andEgypt, as well as in lessobvious markets such as Spain, Argentina, Guatemala,Tanzania, Russia and Uzbekistan. Mills range from firsttime entrants inautomatic winding to sophisticated users with very high quality demands. Theyspan environmental conditions from 10 degrees Celsius to 53 degree Celsius,from 20 percent relative humidity to 80 percent. Over 300 fiber types wereprocessed, including traditional cotton, polyester, viscose and their blends aswell as flax, modal, Tencel, silk, cashmere, elastane and nonelastane coretypes. These facts prove USTER®QUANTUM3 is flexible enough to handle varying conditions, applications andexpectations. But what are the customer benefits in terms of quality andproductivity?

[--page--]

最佳的清紗設限:簡單、快速

Optimalclearing limits: quickly and simply

客戶們都很欣賞紗體這一概念,它使得系統的應用更加簡單。并且達到最佳的清紗界限非常快速、簡單——之前一直處于爭論之中,如今客戶都接受紗體這一概念并作為清紗的一個必要元素。

Customerswere united in their appreciation of the YARN BODY concept, which made thesystem much easier to use. It was easy and fast to arrive at an optimalclearing limita factor which was always a matter for debate with users nowwelcoming the YARN BODY as an essential element in yarn clearing.

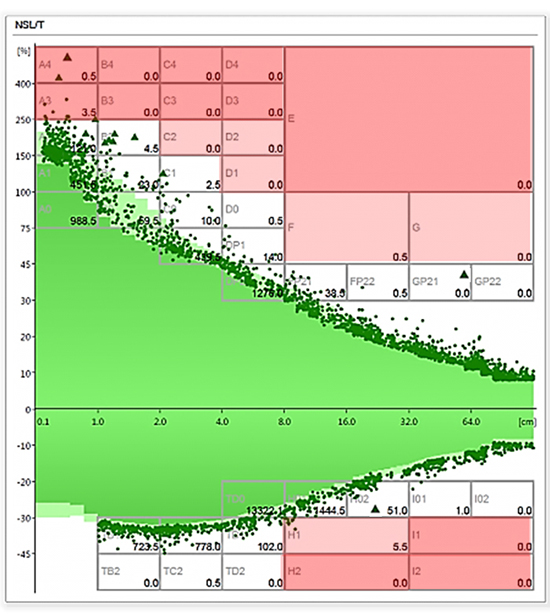

許多客戶也反饋到質量投訴的減少,特別是針對條干更均勻的紗線,如緊密紡紗。之前,清紗界限不能清除這些紗線的異常,因為紡廠經常遵循“分級清紗”。紗體一覽圖使得這些紗疵更為直觀明顯,而紡廠也能相應地調整設限。如下圖USTER®CLASSIMAT 5上的示例(圖1和圖2)清晰顯示了這些反饋的影響。紗線是緊密紡紗線,但是清紗使用的是傳統的分級清紗導致一些紗線異常仍然存在,圖中顯示的深綠色的小三角——USTER®CLASSIMAT 5的紗線分級系統的一項特殊功能。

Many customers also reported the elimination ofquality complaints, especially with more even yarns such as compact yarns.Previously, clearing limits had been unable to eliminate outliers for theseyarns, as spinning mills often followed the 'class clearing' approach. The YARNBODY view made these faults much more obvious, and mills were able to adapt thelimits accordingly. The example below (fig. 1 and 2) from the USTER®CLASSIMAT 5 clearly shows the impactof this feedback. The yarn is a compact yarn, but clearing using traditionalclasses left some remaining outliers in the yarn, indicated by the dark greentriangles – a special feature of the USTER®CLASSIMAT 5 yarn classification system.

圖一_緊密紡紗,使用傳統分級清紗后仍存在異常(深綠色三角形)

[--page--]

圖二_普梳紗,清紗極限切入紗體(利用傳統的分級清紗)

由于紗體一覽圖的出現,紡廠能在無需大幅增加切次的前提下清除異常。同樣還有很多例子說明紡廠所設置的清紗界限范圍太小。多虧了紗體的可視化,紡廠才能糾正這種設置并能夠減少浪費、提升產能,同時能創造更高的利潤。

As a consequence of the YARN BODY view, spinners hadmoved closer to eliminating outliers without increasing the cuts significantlyin such cases. There were also many examples of spinning mills definingclearing limits that were too close. Thanks to the YARN BODY visualization theycould correct them resulting in saving waste and in increasing productivity,both leading to higher profits.

識別生產過程中的問題

Identifyingprocess disturbances

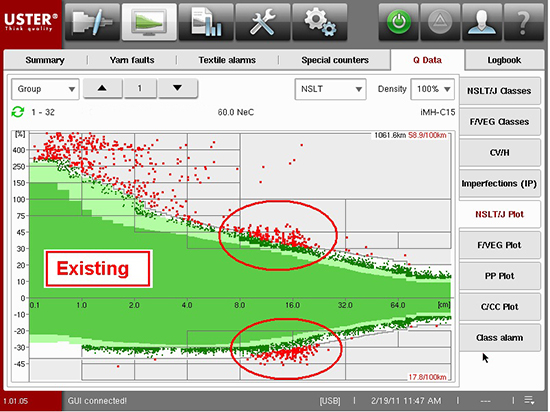

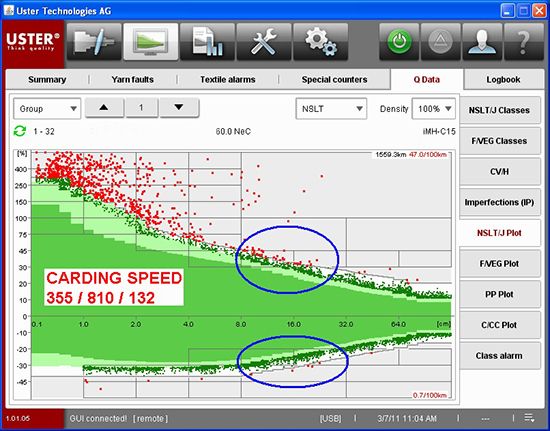

據一些紡廠經理報告,他們已經將這些變化應用到日常工作中了。因此他們能夠在工廠巡查的時候隨機地查看紗體。“紗體是加工過程及原料狀況的顯示器——如果形狀上有什么異常,更大的淺綠色區域就會產生,我們就能討論如何去改善。”巴基斯坦的一名客戶如此說道。許多有著高品質需求的紡廠也進行了這些嘗試來監察紗體的改變,利用散點圖來發現生產過程的問題并提出改善意見。例如(圖3及圖4),一家印度的紡廠注意到在8-32厘米區域有著許多紗疵。這一現象觸發了相關的調研,并最終實現了最佳的梳棉機速度設定以及切次、織物質量的大幅提升。

Some millmanagers also reported they had implemented changes to their routines, so thatthey were now checking the YARN BODY randomly during patrols in the mill."The YARN BODY is an indicator of process and raw material situation ifsomething was unusual in the shape or a larger light green area triggered, wecould discuss some improvements," explains a customer in Pakistan. Anumber of mills with higher quality demands also carried out trials to monitorthe changes in the YARN BODY, using scatter plots to find process issues andsuggest improvements. For example (fig. 3 and 4), a mill from India noticed anunusual number of events in the 8 cm to 32 cm area. This triggered investigationsleading to optimum carding speed settings and considerable improvement in cutsand fabric quality.

[--page--]

圖三_紗體應用之前,在8-32厘米區域的紗疵

圖四_紗體應用之后,調整梳棉機速度之后的提升改善

此例以及其他許多例子,都印證了紗體作為一個能幫助迅速認識并理解紗線條干及變異的優良參量的價值。總的原則為:紗體越窄,織物質量越好。這一比較工具已被應用到USTER®CLASSIMAT 5。

[--page--]

This, and many other examples, underlined the value ofthe YARN BODY as a good parameter to gain an understanding of the yarn evennessand its variations, at a glance. The general rule is: the narrower the YARNBODY, the better the fabric quality. A comparison tool is now incorporated intothe USTER®CLASSIMAT 5.

同時也有一些紡廠報告到在管理這一創新的多功能系統過程中的遇到的初期困難。大體的反應是決心應用后變得更有效率,即使這意味著在流程上得有所改變。“我聽許多客戶反映他們如何重視易用性以及清紗設限建議”Sivakumar Narayanan,烏斯特公司清紗器產品經理如是說道。“事實上,一些客戶告訴我們,他們已經不記得在應用USTER®QUANTUM 3 紗體概念之前,他們是如何設定清紗曲線的了”。

While some mills reported initial difficulties inadapting managing the innovative multiple systems, the general reaction was adetermination to improve and become more effective, even if this meant changesin procedures. “I have heard from many customers how much they value the easyuse and the clearing limit proposals”, says Sivakumar Narayanan, ProductManager of Yarn Clearing, within Uster Technologies Ltd. “In fact, somecustomers told us they could hardly remember how they operated their yarnclearing installations before the YARN BODY concept with USTER®QUANTUM 3.”